Efficient cutting with the VN-300 Z series

Fully automatic cutting system – combined with manual infeed and outlet for flexible workpiece processing.

The VN-300 Z wet cut-off machine was developed for precise and repeatable cuts on small to medium-sized workpieces. Its fully automatic cutting process ensures consistent quality, while manual infeed and outled allow for flexibility in workpiece handling. This makes the series ideal for use in series production as well as for individual cutting tasks in laboratories or workshops.

Suitable for the trimming of:

- Hard metal bars with a length of up to 300 mm and Ø 30 mm

- Pipes and other bar materials in wet cutting mode

Your benefits at a glance:

Digital length measurement

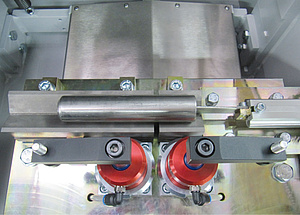

Precise, stepless adjustment and repetition of the cutting length – quickly and without readjustment.Double clamping device

Two parallel clamps for vibration-free fixation and precise, repeatable cuts.Prism clamping with digital stop

Pneumatic swivel clamps for secure, fast clamping – with digital positioning for reproducible results.3-zone cutting area

Individually adjustable cutting parameters for optimum quality and maximum service life.

Technical details of the VN-300 Z series:

| Main motor 400 V, 50 Hz, 3-phase rotary current | 4.0 kW |

| Max. cutting wheel size | 300 x 2.5 x 32 mm |

| Circumferential speed fixed | 45 m/s |

| Clamping surface table | Width x Depth: 350 x 250 mm, 7 T-slots: 14 mm DIN 650 |

| Z-axis-cutting wheel adjustment, using servo axis | 200 mm |

| X-axis-longitudinal machine table adjustment, using servo axis | 285 mm |

| Y-axis-cross machine table adjustment, using hand wheel | 40 mm |

| Coolant pump | 25 l/min |

| Machine dimension with hood closed (Width x Height x Depth) | 1,000 x 800 x 1,000 mm |

| Weight | 280 kg |

| Electrical connections 230/400 V, 50 Hz | 4.6 kW / 16 A |

Optional:

Magnetic or belt magnetic filter unit –

filters metal particles from the cooling lubricant – for longer service life and clean cut surfaces.Laser cutting line indicator and infeed and outlet and removal units –

marks the exact cutting position and facilitates precise alignment – for repeatable, efficient work.Openings for longer parts–

enable the machining of extra-long workpieces without modifications.Base cabinet and infinitely variable speed control –

offers storage space and allows optimal adjustment of the cutting speed – for high cutting quality and low wear.

Pütz Group – a strong association of specialists.

Our network of experts optimizes your production for maximum efficiency.