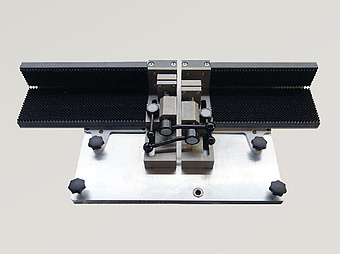

Wet cutting machine series MN-400 A3 S

More efficiency and profitability for your separation tasks

The cutting machine serie MN-400 A3 S is highly versatile: for test cuts (metallography), the cutting to length of bar materials and other applications, such as the machining of pre-positioned workpieces on a quick-change system.

It is suitable for use both in production and quality assurance.

All SilverCut machines are certified with the CE mark in accordance with VDE and UVV guidelines.

Your benefits:

- For universal use

the cutting machine performs a range of different cuts: longitudinal, chop, oscillation and pulse cuts - Low-maintenance, servocontrolled electric cylinder

for cutting wheel feeds - Convenient

cross table with indexing and recognition of quick-change system - Efficient

cutting disc measurements in adjustable intervals with automatic speed adjustments - Clean and solid

feed and discharge systems lined with stainless steel drip trays including coolant return inside the machine - Integrated coolant circulation system

- Easy to use

manually adjustable measuring stop with digital display and zero-point change - Secure

closed system with a large safety screen in the sliding door for excellent process monitoring

Technical details:

| Servo axes | X-longitudinal table/Y-cross table/Z-cutting disc feed |

| Generous travel paths | |

| Cutting disc sizes | 200 mm – 400 mm |

| Drive power | 10 kW |

| Infinitely variable speed range | 30 – 63 m/sec |

| Clamping table size | 400 mm x 450 mm with indexation |

EVERYTHING FROM A SINGLE SOURCE

Thanks to our integration into the PÜTZ GROUP and the resulting

synergy effects we are able to offer you not just production and

specialist cutting machines but also the appropriate testing technology

to test surfaces as well as dimensional accuracy.