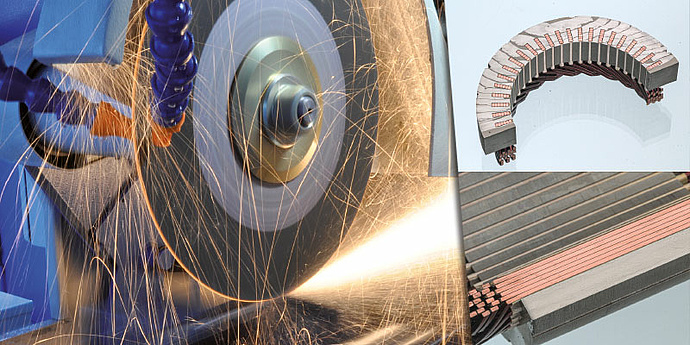

Cutting of hairpin stators

Flexible cutting machines to quality control the drives of tomorrow!

The growth of electric mobility is placing new demands on the cutting machines used in metallography. Many machines reach their limits when cutting hairpin stators: the work area is just too small. Stators often have to be cut in advance, which is laborious and time consuming. Cuts of the laminated core and copper pins require a constant surface quality to determine the fill factor. The flexible SilverCut cutting machines master these tasks and are available to you today – for the cutting tasks of tomorrow!

Your benefits:

- Technological support to help you choose the right cutting disc (to cut copper and steel)

- Large work area, whereby whole stators can be clamped and cut

- Precise cuts through the middle of the slot

- Fill factor detection without post-processing

- Flexible cuts for chop, pulse, longitudinal or oscillation cuts

- Controlled cutting paths thanks to programmable cutting parameters

We‘re here to help!

- with the selection or construction of suitable clamping devices

- with the selection of the right cutting process

- with the selection of the right parameters

- with the selection of the right cutting disc

EVERYTHING FROM A SINGLE SOURCE

Thanks to our integration into the PÜTZ GROUP and the resulting synergy effects we are able to offer you not just production and specialist cutting-off machines but also the appropriate testing technology to test surfaces as well as for dimensional accuracy.